- Home

- About Us

- Machines

- Cups & Containers

- Support

- Contact Us

- Customer Portal

Service Bulletin: SB 185.4

Subject: Thrust Bearing, Split Flange Bottom Finish Tooling — To Extend the Service Life of Ramp Style Bottom Finish Station Tooling

Recommendations:

Click here to view SB 185.4 PDF

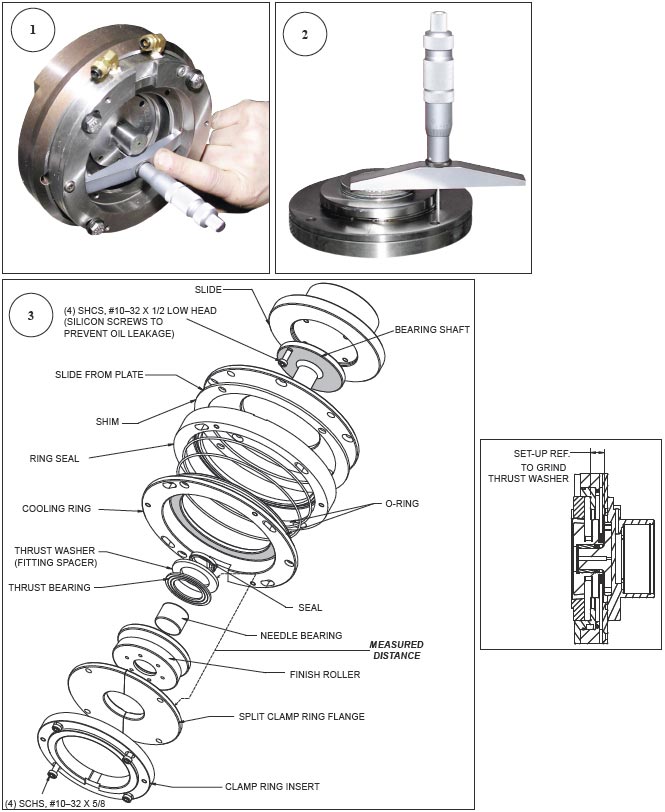

PMC, in a continuing effort to engineer an improved product, is pleased to offer a thrust bearing, split flange bottom finish roller assembly for the ramp style station. The new design provides longer service life with less downtime as long as regular maintenance is performed. To change from the design being used on your machine to the new design, the thrust washer needs to be ground for the correct fit.

INSTRUCTIONS:

EXAMPLE: (A) – (B) + .001″ = (C)

Grind (C) from the thrust washer

After installing the parts, run the machine to achieve operating temperature (approximately 1/2 hour). Cycle stop the machine and check the Roller to ensure it still rotates freely. Due to expansion rates, it may be necessary to remove an additional 0.001″– 0.002″ from the Thrust Washer/Fitting Spacer.

MAINTENANCE:

Once a week remove the bottom finish roller assembly from the station, clean the parts, inspect the parts (for damage or wear), and re-assemble. Prior to re-assembly, coat the flange with a film of grease and repack the needle bearing using Chevron Rykon EP 2 (HW-16629), Mobil Polyrex EP 2, or equivalent.

PURCHASING INFORMATION:

Information and pricing for the parts listed above can be obtained by contacting the Customer Service Department at Paper Machinery Corporation. Parts orders and customer communication can now be sent directly to the service department on Fax number 414-354-1710.